Current Not Detected

If this occurs this will more than likely result in atleast the next weld not being analyzed which will be displayed as a white "no rating" in the browser.

Case 1: No Weld Captured

In this case, RIWA did not see a weld before it timed out. The weld timeout parameter should be increased.

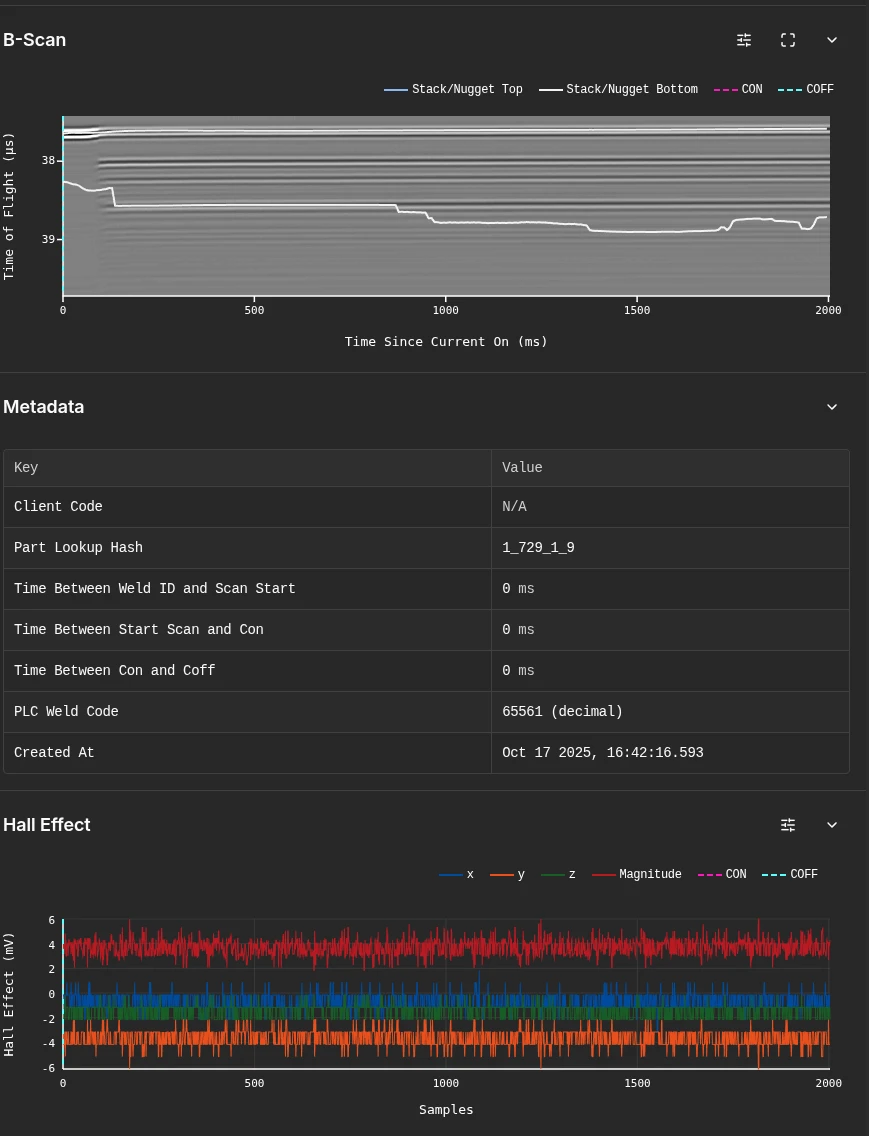

Case 2: Weld Captured but not detected

Here, RIWA saw the weld but did not accurately detected the current on and off events. This means the Hall Effect parameters should be modified. To do this, run the following steps in the configurator:

- Navigate to the Catalouge Menu.

- Choose a Part Group that contains the affected weld.

- Select the Part the affected weld belongs to.

- Select the affected weld type.

- Modify the Standard Deviation threshold for the Hall Effect sensor.

- Increase to reduce false positives.

- Decrease to reduce false negatives.

- Test, and repeat step 5 until current ON and OFF are detected properly.